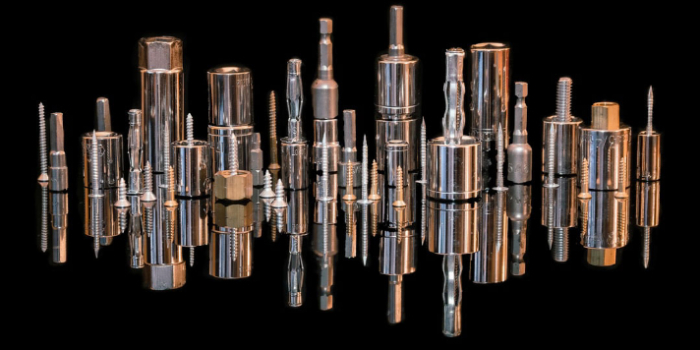

Whether you are working on a small house chore or a major industrial project, the screws used in executing the work will matter. Your project may require a custom captive screw, or it may require custom screws. You may need small screws; and if that is the case, your options range from micro screws to tiny screws and more. Fortunately, the nut, bolt, & screw industry has a wide range of options for you to choose from. Here is a look at some screws and their functions.

Check out our EZ Screw Builder to build your custom screw!

Screw Point Types

There are many different kinds of screw points. Each one is designed for a particular type of use, ranging from sheet metal to wood. Here are the five most common types groups of screw points. Machine and tapping screws, self-drilling screws, thread forming screws, thread cutting screws, and tapping screws. It is important to note that within each category there are several different types of points, each designed for a specific function.

Plastic Thread Forming Screws

Thread forming screws for plastic are in great demand today. For instance, the captive screw is a fastener that has been created to fit into holes that have already been drilled. This is a low-stress method that lessens the impact and reduces the likelihood of losing screws or cracking off pieces of plastic. These thread forming screws (such as the captive thread fastener) are especially effective for use in cell phones, laptops, and other devices. They are durable for assembly and disassembly and they resist loosening caused by vibrations. Among the variety of plastic thread forming screws includes delta PT, Hi-lo, plastite, trilobular, and more. As with all screws, it is important to emphasize the Critical nature of torque screws to the proper value. If they are too tight, they risk breaking. And if they are not tight enough, the may become loose or disengage. Either option is a scenario that should be avoided at all costs.

SEMS Screws

There are many advantages to using SEMS screws. They are permanent fasteners, they are fast to use (which increases production), and most of all, they can be used in a wide variety of products. The ingenious design of the SEMS screw actually is a co-joining of two separate screws, and the two parts that are joined create one unique fastener. Another major advantage is that they are low-cost items.

Summary: The Captive Screw and Other Screw Types

To sum up, the captive screw and other screw types are an integral part of the American industrial business environment. This is a thriving economic factor in the country, with 131,949 people being employed by the nut, bolt, and screw industry in the United States. To keep business owners and customers satisfied, innovative engineering continues to produce nuts, bolts, and screws that will help keep up with developments and demand.