The concept of the screw has existed as far back as around 200 B.C. Today, there are many types of captive fasteners that can be useful for a variety of functions. Knowing about some of them can help you decide what to use in certain situations. Here are a few different types of captive fasteners that you can consider for your next project.

Check out our EZ Screw Builder to build your custom screw!

1. Captive nuts

Captive nuts are fasteners that are internally-threaded. It’s a nut that is wrapped up in a spring steel cage. They’re designed to quickly connect with studs. These fasteners are effective for blind locations and are usually able to be attached without doing damage to panel finishes. In contrast with threaded holes, captive nuts can be replaced if they’re over tightened, and are easier to use on materials that are too soft to be threaded. This specific fastener is typically utilized in industrial and electronic applications. They mount equipment in square-holed racks.

2. Weld nuts

A weld nut is a fastener that is designed for welding to another object. It’s usually made of stainless steel or low carbon steel. There are several kinds of these fasteners that can be used for various applications. Single tab weld nuts are used for heavier gage materials. Retainer weld nuts have a floating nut that is held within a retainer. This design allows for misaligned or off-center screws to be installed. The nut floating freely helps to compensate for any building inconsistencies. Other types of weld nuts that are used include four projection weld nuts, twin pilot weld nuts, and slab base nuts.

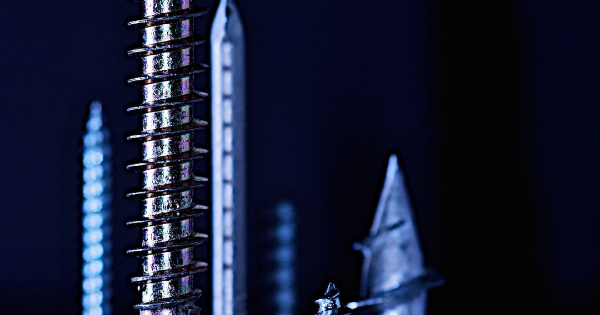

3. Captive screws

Captive screws are fasteners that are used in equipment panel assemblies and PC boards. These include signs, network cabinets, medical devices, and electronic enclosures. You can usually identify them by their threaded end and unthreaded shank. The design allows it to be locked into pre-drilled holes in order for the screw to be unfastened and fastened without any detachment. Captive screws can be combined with springs, retainers, and washers to put together a self-captivating assembly. These captive fasteners can be effective in fastening applications where vibration shock, thermal expansion, and thermal conductivity are involved. In addition, captive screws are useful in situations where quick assembly and disassembly is required, and they can prevent screws from falling into electrical circuits or getting lost.

Screws are essential for keeping objects together so machines or devices can function properly. The type of fastener you choose will depend on what type of project you’re working on. These are a few of many different types of captive fasteners that are useful for tightening different objects.

Related Articles

When it comes to product design, every detail matters. From the choice of materials to the manufacturing process, every decision can significantly impact the functionality, durability, and aesthetics of a...

Spending $1500-$3000 on a custom screws may seem excessive to some, but for designers and engineers who are passionate about their craft, it can be a necessary expense to solve...

Tamper proof screws are an important security feature for many industries, including electronics manufacturing, aerospace, and government. They are designed to prevent unauthorized access to sensitive equipment, products, or areas...